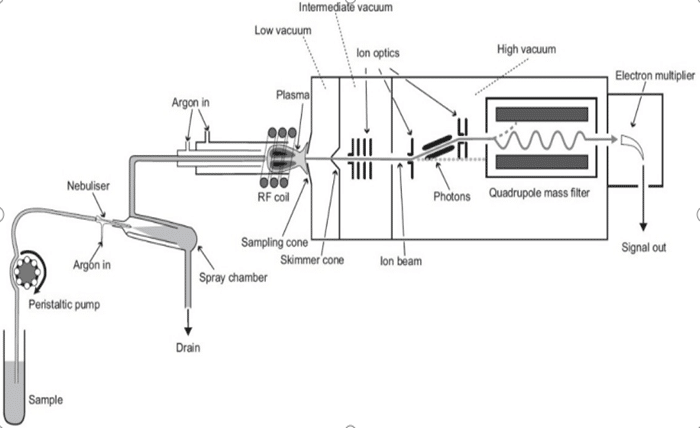

ICP-MS (Inductively Coupled Plasma Mass Spectrometry) is a strong analytical instrument utilized in a variety of scientific disciplines. Proper maintenance ensures that your ICP-MS runs smoothly and provides accurate data for analysis. With complicated components and precise functions, this device requires frequent maintenance. Following best practices for regular maintenance saves downtime, lowers repair costs, and assures long-term efficiency. This checklist gives clear information on the necessary maintenance chores to keep your ICP-MS functioning smoothly, hence ensuring accuracy, consistency, and lifespan.

Why Is Regular ICP-MS Maintenance Critical?

Preventing Downtime and Costly Repairs

Routine ICP-MS maintenance is necessary to avoid unexpected malfunctions, which can result in costly repairs and lengthy downtime. Without frequent checks, minor flaws might grow into major problems, affecting research or manufacturing operations. By following a maintenance schedule, probable problems are identified early on, reducing the risk of equipment faults and operating delays. This proactive strategy guarantees that the instrument stays operational, lowering the danger of lengthy downtime while preserving production.

Ensuring Accurate and Consistent Results

Accurate and reliable findings are at the heart of ICP-MS performance. Regular maintenance ensures that all components, from the nebulizer to the mass spectrometer, work as intended. Dust, corrosion, and wear can all reduce reading accuracy over time, resulting in incorrect findings. Routine tests, such as calibration and component inspection, help preserve your instrument’s accuracy. Keeping the ICP-MS in good condition guarantees consistent results, which are essential in research, quality control, and other analytical applications.

Extending Instrument Lifespan and Performance

Regular maintenance not only assures accuracy but also extends the life of the ICP-MS. Addressing minor faults early reduces wear and tear on vital components, lowering the need for costly repairs or replacements. Routine checkups and cleaning guarantee optimal performance, allowing the instrument to operate at top efficiency. Regular service also helps to prevent component deterioration, which can cause performance concerns over time. A well-maintained ICP-MS performs better, lasts longer, and requires fewer repairs, which saves you money over time.

What Are the Essential Daily, Weekly, and Monthly Tasks?

Daily Checklist: Rinse Systems and Inspect Cones

Daily maintenance duties for ICP-MS are crucial to ensure proper operation. Begin by washing the sample introduction system with suitable solvents to eliminate any remaining samples or debris. Inspect the cones for signs of wear, corrosion, or clogging, which can compromise sensitivity and function. In addition, inspect the nebulizer for any obstructions and confirm that the aerosol is correctly created. These brief daily chores serve to prevent contamination, keep the system stable, and reliably produce data.

Weekly Tasks: Torch Cleaning and Nebulizer Checks

Weekly maintenance entails a more thorough check of important components. Clean the torch to prevent salt or sample residue accumulation, which can have an influence on plasma stability and sensitivity. Inspect the nebulizer for clogging or wear, since these issues might have an impact on sample introduction accuracy. It is also important to monitor gas flow rates to maintain constant functioning. Weekly chores maintain the ICP-MS functioning smoothly, ensuring that performance does not degrade between daily inspections.

Monthly Routine: Vacuum System and Pump Maintenance

Monthly maintenance should prioritize important subsystems that support ICP-MS operations. Begin by checking the vacuum system for leaks or performance difficulties, as a steady vacuum is required for precise readings. Also, inspect and replace peristaltic pump tubing as needed, as worn or broken tubing might impair sample delivery. Inspect the cooling system, change any filters, and ensure that the pump is operating properly. Regular maintenance of these components will extend the instrument’s life and keep it running at full potential.

Which Parts Require Frequent Inspection or Replacement?

Sample Cones and Interface Cones

The sample and interface cones are critical components of the ICP-MS system, since they directly influence the transport of ions from the plasma to the mass spectrometer. Frequent inspection is required to check for wear, clogging, and corrosion, which can all affect performance. These cones should be cleaned on a regular basis and replaced when they show symptoms of substantial deterioration. Replacing worn or broken cones promotes correct ion transfer, guaranteeing maximum sensitivity and efficiency in analysis.

Peristaltic Pump Tubing and Nebulizers

Peristaltic pump tubing and nebulizers are required for reliable sample delivery and aerosol production. Tubes can degenerate over time owing to wear or exposure to harsh chemicals, and nebulizers can clog or lose efficacy. Inspect these components on a regular basis for wear, blockages, or cracks, and replace them as needed to avoid inconsistencies in sample introduction. Maintaining these components is crucial to ensure that the ICP-MS system produces accurate and consistent findings.

Torch Components and Spray Chambers

Torch components and spray chambers have a significant impact on plasma stability and precision. Regular examination and repair of torch components, including the injector and spray chambers, is required to prevent blockage or contamination. Cleaning and replacing worn-out parts will help to preserve plasma stability, decrease interference, and improve measurement sensitivity. These components must be examined and repaired on a regular basis to prevent performance difficulties and ensure high-quality output.

Conclusion

Routine maintenance is an integral part of ICP-MS operation, ensuring that the system remains accurate, reliable, and efficient. By doing the same maintenance jobs every day, every week, and every month, users can make their instruments last longer, avoid expensive repairs, and get regular results. Key parts like cones, nebulizers, and pumps should be checked and replaced on a regular basis to make the system work better and last longer. If you follow these care tips, you can make sure that your ICP-MS gives you accurate data for many years to come.