RUD manufactures specialised lifting points that handle the precise demands of aerospace manufacturing and aircraft maintenance operations. The lifting points feature advanced materials, standard testing protocols, and precision engineering specifically designed for high-stakes aerospace environments.

You know how stressful it gets when you’re working with aerospace components worth hundreds of thousands of dollars. When you’re dealing with such valuable parts, every lift needs to be perfect, and every connection has to hold.

Our team at RUD Australia specialises in engineering these exact solutions for defence and aerospace clients who can’t afford to take chances.

In this article, we’ll show you:

- Standard lifting gear’s limitations in aerospace environments

- RUD lifting points and their extreme precision capabilities

- Where these systems prove their worth in real-world applications

- What makes these systems worth the investment for your operations

Let’s dive in and see what proper lifting gear can do for your aerospace operations.

The Essential Demands of Aerospace Lifting

Successful aerospace lifting requires non-negotiable elements, like absolute precision, zero failure tolerance, and complete traceability of every component. Since each aircraft part carries enormous value and risk, personnel safety depends on flawless execution every single time.

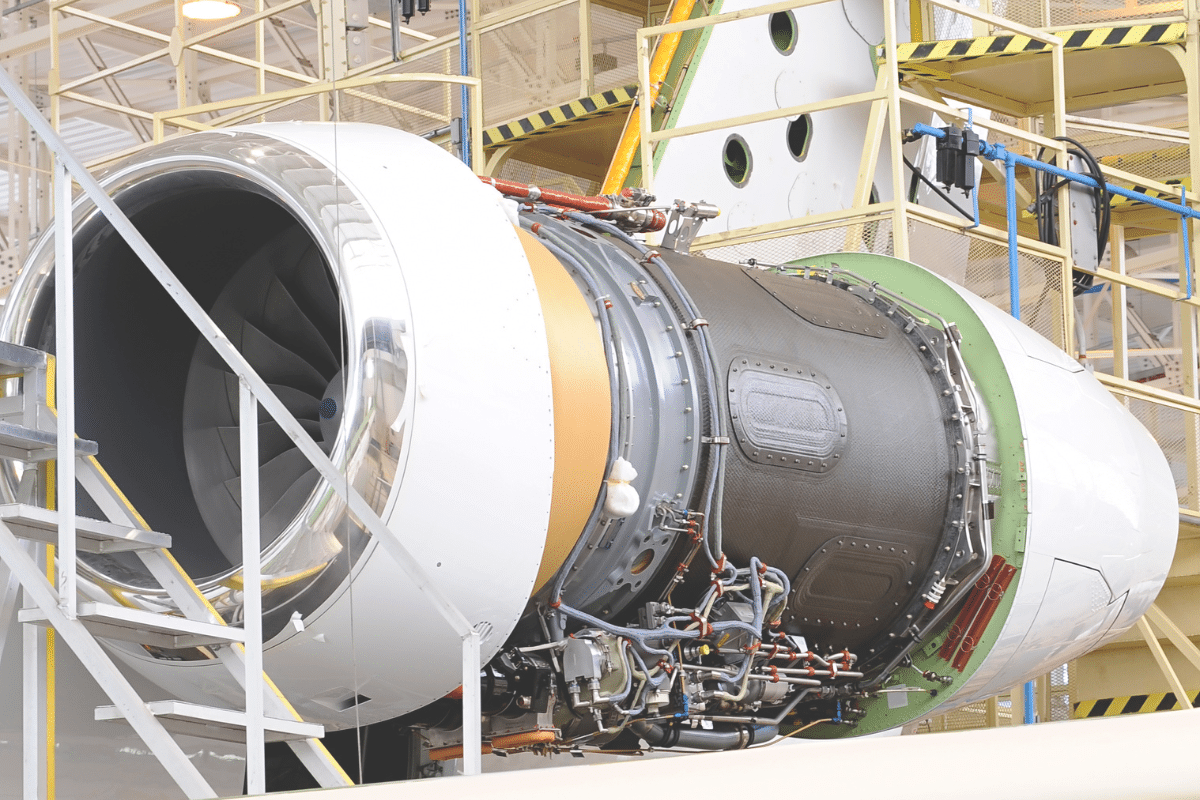

Suppose you’re moving a $2 million engine section onto an aircraft frame. Engineers measure the clearance in millimetres, and dozens of workers are positioned around the lift zone. In situations like this, standard industrial lifting gear simply can’t handle this level of precision and accountability. The stakes are too high, and frankly, the margins for error are non-existent.

Why Standard Equipment Falls Short

Besides these precision demands, defence lifting gear must also withstand extreme conditions while maintaining perfect performance records. That means these environments need safe equipment that performs consistently under pressure, temperature variations, and corrosive conditions.

However, standard equipment is designed for general industrial use, not the demanding aerospace environment. So it often fails when exposed to the harsh chemicals, extreme temperatures, and corrosive materials common in aircraft manufacturing. What’s more, aircraft assembly and maintenance present unique demands that extend far beyond typical industrial applications.

Unfortunately, regular lifting equipment lacks the precision controls and safety features needed for aerospace work. After all, you can’t exactly call a breakdown service when you’re working on classified defence projects at 2 AM. These projects operate on strict timelines where equipment failure is both inconvenient and unacceptable.

That’s exactly why you need lifting solutions that address these demanding requirements through advanced engineering and strict adherence to industry standards. Our approach goes far beyond standard lifting solutions to meet these exact challenges.

RUD’s Advanced Engineering and Compliance with Standards

What makes RUD lifting points different from standard industrial equipment? The answer lies in our thorough testing protocols, international certification compliance, and continuous product innovation customised for high-stakes applications.

Unlike standard manufacturers, RUD Group engineers solutions that meet the exact demands of aerospace and defence operations where precision is never compromised.

Let’s look at how we achieve this precision and reliability through two main approaches:

Meeting Strict International Standards for Defence

RUD’s lifting points undergo extensive testing and certification processes to meet international standards required by defence forces worldwide. This comprehensive approach ensures our product range carries certifications that satisfy the Australian Defence Force’s strict requirements for safety and performance.

When defence forces buy equipment, they follow strict guidelines that require suppliers to show their gear meets specific performance and safety requirements. That’s exactly why every RUD solution goes through detailed testing before it reaches your facility. Plus, our certifications include compliance with relevant ISO standards for lifting equipment and quality management systems.

The testing process covers load capacity, fatigue resistance, and environmental durability. Most importantly, these tests prove that RUD’s solutions can handle real-world defence applications where failure is never an option. Isn’t that exactly the assurance your operations want?

Complete Product Innovations for Specialised Needs

If your aerospace operations require precise lifting solutions, then RUD’s product range offers innovations designed specifically for aircraft components and the aerospace industry. Our lifting products feature advanced materials and engineering that regular industrial equipment simply can’t match.

One of our clients recently shared their experience with RUD’s engineered lifting solutions. Their Managing Director even left positive feedback mentioning how we provided a controlled drive solution for an engineered lift that fulfilled all of their requirements. This is the kind of reliable performance every aerospace facility wants to hear about.

Now that you understand our engineering standards and product innovations, let’s see how we customise these solutions to address your unique aerospace challenges.

Customised RUD Solutions for Aerospace’s Unique Challenges

RUD’s solutions are specifically designed to handle the complex weight distribution, precise positioning, and extreme safety requirements of aerospace lifting. Each system gets customised to match your exact operational needs rather than forcing you to adapt to generic equipment.

We understand that aerospace work demands solutions that perform flawlessly under the most demanding conditions. Your operations need equipment that addresses specific challenges rather than generic solutions that compromise on precision and safety.

Here’s how we address these specific challenges through three focused approaches:

Customisation for Highly Specialised Components

Ever tried lifting a delicate radar assembly or positioning a turbine blade that costs several hundred thousand dollars? Then you know that standard lifting solutions just don’t work when precision is this important. You need customised solutions designed specifically for aerospace components that demand millimetre-perfect placement.

We work with clients on parts like:

- Engine housings

- Wing assemblies

- Avionics systems

- Composite panels

Major aerospace manufacturers have relied on our strong engineering approach to handle their most sensitive parts. Your components need specific solutions around weight, shape, and handling requirements. And when you use lifting technology that adapts to your most complex challenges, you’ll get equipment that works exactly how you need it to work.

Optimising Efficiency and Safety in High-Value Operations

When you’re working with million-pound aircraft parts, every lift needs to balance speed with absolute safety. Your valuable aerospace parts need to be safe, even if productivity and risk factors increase. In that scenario, you need lifting points that streamline your operations without compromising the safety standards your industry demands.

There’s solid data to support this approach. Research shows that the rate of nonfatal injuries and illnesses in the aircraft manufacturing industry dropped from 3.4 to 2.8 per 100 workers within a year. This steady improvement proves how consistent use of safety protocols and well-maintained equipment can drive a measurable impact on workplace incidents.

If you build aerospace solutions with a specific purpose, they eliminate uncertainty and reduce the steps needed for each lift. That’s because the customised solutions are specifically designed for your type of work instead of being adapted from general industrial use.

Pro tip: Track your lifting times before and after adding specialised solutions to your operations. Most facilities see immediate improvements in both efficiency and measurable safety performance.

Unparalleled Long-Term Support and Client Partnership

One point of pride for RUD is our long-term customer care, which includes regular inspections, maintenance, and safety updates. This partnership approach opens up new opportunities for process improvements and equipment upgrades as your operations grow.

Most suppliers disappear after the sale, but the ones who truly care about your success stick around to make sure your equipment keeps performing like it’s supposed to. Our clients appreciate having a dedicated partner who understands their specific challenges and can respond quickly when they need support or advice.

Making the Right Choice for Your Lifting Needs

Aerospace lifting demands uncompromising quality and innovation to handle high-value components safely. However, with specialised solutions, you can address these concerns and operate with measurable performance improvements across your facility.

We’ve explored how precision requirements drive equipment choices and examined advanced engineering standards. You also learned how customised solutions increase productivity while maintaining safety standards that protect both personnel and valuable assets.

Now you know what separates standard equipment from aerospace-grade solutions. When you’re ready to discuss lifting solutions that match your aerospace requirements, we’ll be happy to help.